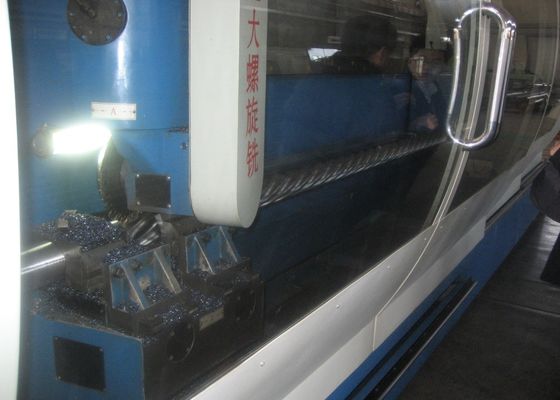

Downhole Motor Rotor Milling Machine CNC Screw Milling Machine

The CNC screw milling machine tools is mainly used for rough milling of downhole mud motor and screw type section of stator spindle. It features with high speed, high efficiency, high reliability and consistent processing part. Human factors have very limited impact on the processing.

Main transmission system

Spindle motor of CNC screw milling machine drives spindle motion by gear change mechanism. It features with simple structure, easy maintenance and high reliability. Speed change is realized by main motor frequency control. When adopting frequency control, stepless speed variation is realized. Positive and negative rotation of spindle is controlled by electric system. Positive and negative rotation has the same speed.

Work piece locking system

The CNC screw milling machine is equipped with the work piece locking system, power source is hydraulic. It is locked by lock sleeve, connect with angling cylinder by pull rod. When position in the angling cylinder moves forward and backward by hydraulic force, wedge-shaped parts in hydraulic chuck drive jack catch tight or release. The matched hydraulic system has one-way valve. Magnetic valve is designed to clamp when power is off. It ensures that when power is off suddenly or hydraulic source breaks down, workpiece can still be clamped reliably.

Feed drive system

Feed movement of X axis and Z axis is realized by letting two servo motors connecting ball lead screw nut by coupling, and then transmit to big carriage and small carriage by ball lead screw nut. Ball lead screw nut is pre-tightened, which will realize high precision grapless movement. Rotational movement of Y axis is achieved by driving a SEW gear reducer by servo motor. The structure is simplified to the largest extent and maintenance is easier.

Specification

| Maximum Rotating Diameter |

350mm |

| Maximum Machining Length |

5000mm |

| Spindle Speed |

300r/min |

| X axis stroke |

250mm |

| Z axis stroke |

5000mm |

| X axis maximum movement speed |

5000 mm/min. |

| Z axis maximum movement speed |

8000 mm/min. |

| Tail bed maximum stroke |

180mm |

| Spindle motor power |

9KW |

| Lubrication oil pump power |

40W |

| Hydraulic oil pump power |

4KW |

| Cooling water pump power |

0.75KW |

| Chip cleaner power |

1KW |

| Workholding power source |

hydraulic |

| chuck locking power source |

hydraulic |

| tip power source |

hydraulic |