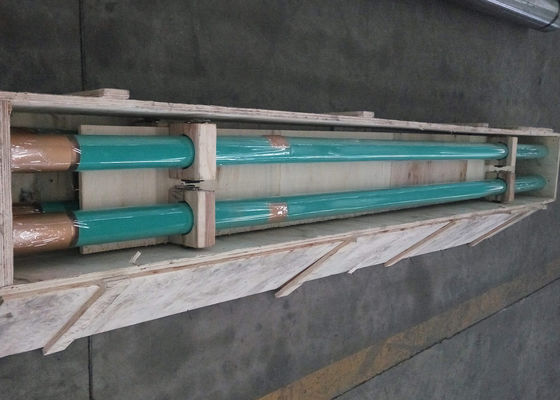

4 3/4'' Downhole Mud Motor for Directional Drilling, HDD Service, 4/5 lobes, 6.0 stages

Downhole mud motor is a kind of downhole dynamic drilling tool upon the power of drilling mud. Mud stream from the outlet of mud pump flows through a by-pass valve into the motor. This stream produces pressure loss at both inlet and outlet of the pump, to push the rotor into rotating, and to transmit the torque and speed onto the bit. The downhole motor property mainly depends upon its property parameters.

Tipotop offers a wide range of configurations to accommodate different types of drilling and drilling conditions. Our motors can be set up to match the torque requirements of the bit, flow rates for cleaning, maximum standpipe pressure or high temperature applications.

Tiptop downhole mud motor adopts near bit structure, adjustable universal coupling housing, stabilizers with different sizes, types and structures, and also universal coupling specially designed for large drill bit & large torque with larger torque bearing capacity, better impact resistance performance and running stability, and integral or interchangeable stabilizers with different sizes are available.

4 3/4" SDMM (120mm downhole mud motor)

- Complete with bearing assembly;

- Having bit box connection 3 1/2’’ REG;

- Screw on stabilizer 5 7/8’’ straight 4 Nos. blades;

- Adjustable assembly, connecting rod assembly;

- Power section having configuration 4/5 lobes, 6.0 stages;

- With catch rod mechanism & crossover sub having box connection 3 1/2’’ IF;

- Stator elastomer compatible to resist temperature up to 120 deg C.

Specification

| Name |

Downhole Motor |

| Model |

4LZ120 x 7.0/6 |

| Size |

Ф120 (Stabilizer Ф149) |

| Minor Diameter |

Ф57.60 mm |

| Lobes of Stator |

5 |

| Wave Crest-Trough OD |

Ф57.94 mm |

| Lobes of Rotor |

4 |

| Trough Chrome plating thickness |

0.08mm |

| Crest Chrome plating thickness |

0.20mm |

| Stator & Rotor Interference |

0.34mm |

| Pressure Difference Inspection |

5.5MPa |

| Connected Thread Up |

3 1/2'' IF |

| Connected Thread Down |

3 1/2'' REG |

Models

| Model |

Tool OD |

Bit Size |

Connection Thread |

Lobe |

Stage |

| mm |

in |

mm |

in |

Top |

Bottom |

| 2LZ120x7.0-4-900 |

120 |

4 3/4 |

149-200 |

5 7/8-7 7/8 |

3 1/2REG |

3 1/2REG |

2:3 |

4 |

| 4LZ120x7.0-6-725 |

120 |

4 3/4 |

149-200 |

5 7/8-7 7/8 |

3 1/2REG |

3 1/2REG |

4:5 |

6 |

| 4LZ120x7.0-5-725 |

120 |

4 3/4 |

149-200 |

5 7/8-7 7/8 |

3 1/2REG |

3 1/2REG |

4:5 |

5 |

| 5LZ120x7.0-3-900 |

120 |

4 3/4 |

149-200 |

5 7/8-7 7/8 |

3 1/2REG |

3 1/2REG |

5:6 |

|

| 5LZ120x7.0-4-900 |

120 |

4 3/4 |

149-200 |

5 7/8-7 7/8 |

3 1/2REG |

3 1/2REG |

5:6 |

|

| 5LZ120x7.0-3.3-660 |

120 |

4 3/4 |

149-200 |

5 7/8-7 7/8 |

3 1/2REG |

3 1/2REG |

5:6 |

3 |

| E5LZ120x7.0-3-660 |

120 |

4 3/4 |

149-200 |

5 7/8-7 7/8 |

3 1/2REG |

3 1/2REG |

5:6 |

3.3 |

| 5LZ120x7.0-5-864 |

120 |

4 3/4 |

149-200 |

5 7/8-7 7/8 |

3 1/2REG |

3 1/2REG |

5:6 |

5 |

| K7LZ120x7.0-2 |

120 |

4 3/4 |

149-200 |

5 7/8-7 7/8 |

3 1/2REG |

3 1/2REG |

7:8 |

2 |

| C7LZ120x7.0-3-1200 |

120 |

4 3/4 |

149-200 |

5 7/8-7 7/8 |

3 1/2REG |

3 1/2REG |

7:8 |

3 |

| 7LZ120x7.0-4-896 |

120 |

4 3/4 |

149-200 |

5 7/8-7 7/8 |

3 1/2REG |

3 1/2REG |

7:8 |

4 |

| 7LZ120x7.0-6.5-896 |

120 |

4 3/4 |

149-200 |

5 7/8-7 7/8 |

3 1/2REG |

3 1/2REG |

7:8 |

6.5 |

| 7LZ120x7.0-7-624 |

120 |

4 3/4 |

149-200 |

5 7/8-7 7/8 |

3 1/2REG |

3 1/2REG |

7:8 |

7 |

| 9LZ120x7.0-3.6-1450 |

120 |

4 3/4 |

149-200 |

5 7/8-7 7/8 |

3 1/2REG |

3 1/2REG |

9:10 |

3.6 |

| 9LZ120x7.0-4-900 |

120 |

4 3/4 |

149-200 |

5 7/8-7 7/8 |

3 1/2REG |

3 1/2REG |

9:10 |

4 |

| 9LZ120x7.0-6.5-900 |

120 |

4 3/4 |

149-200 |

5 7/8-7 7/8 |

3 1/2REG |

3 1/2REG |

9:10 |

6.5 |