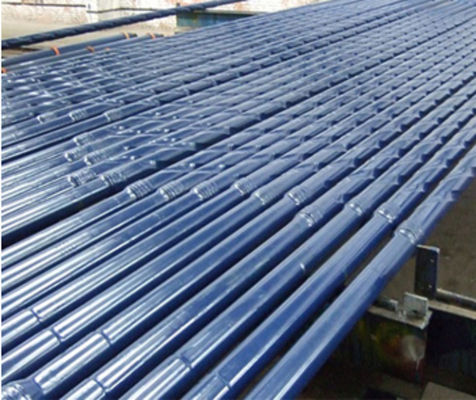

Alloy Steel Oil Well Drilling Tools API Standard Non Magnetic Heavy Weight Drill Pipe

-

-

Large Image :

Alloy Steel Oil Well Drilling Tools API Standard Non Magnetic Heavy Weight Drill Pipe

|

Product Details:

| Place of Origin: |

China |

| Brand Name: |

TIPTOP |

| Certification: |

API |

| Model Number: |

Non-magnetic heavy weight drill pipe |

Payment & Shipping Terms:

| Minimum Order Quantity: |

Negotiable |

| Price: |

Negotiable |

| Packaging Details: |

Iron Frame Packaging |

| Delivery Time: |

3~20 days |

| Payment Terms: |

T/T, L/C, D/A, D/P |

| Supply Ability: |

20000 pcs per month |

|

Detailed Product Description

| Product Name: |

Non-magnetic Heavy Weight Drill Pipe |

Standard: |

API |

| Colour: |

As Required |

Application: |

Well Drilling |

| Material: |

Alloy Steel |

Outer Diameter: |

2 7/8" - 6 5/8" |

| Highlight: |

down the hole drilling tools, downhole oil tools |

Downhole Drilling Tools - API standard non-magnetic heavy weight drill pipe for well drilling

Introduction

The Non-magnetic compressive service drill pipes are made ol tow carbon stainless steel. acc .to ARI Spec .7 and SY/T5144 . All threads are phosphate ,plate copper or cold worked . All Connections are equipped with pressed steel thread protectors . All threads are machined with CMC Lathes-Double-shouldered and special threads.

Mechanical Propertit

Measurements ol rolativo magnetic permeability.

Drill collars shall have a relative magnetic permeability less than 1.010.Each certification of relative magnetic permeability shall identity the test method.

Field gradient measurement Th© magnetic field m the bore of new drill collars shall exit deviation from a uniform magnetic field not exceeding ± O.OSpT.This shall be measured with a magneto scope and differential field probe having its magnetometers oriented in the axial direction of the collar .A strip-chart record showing differential field along the entire bore of the collar be part of the certification of each collar.

Corrosion resistance requirements((or austenitic steel collars ol 12%chromium of more) Austenitic stainless steel collars are subject to cracking due to the joint action ol tensite stress and certain specific corrosive agents. This phenomenon is called stress-corrosion cracking. Resistance to iotergtanular corrosion shall bo demonstrated by subjecting material from each collar to the corrosion test specified in ASTM A262 Practice E .At the discretion of each supplier, the test specimen may have an axial orientation. In which case it shaB be taken from within 12.7mm(0.5 in)of the bar surface, Of it may have a tangential orientation, in wtiich case its midpoint shall be within12,7mm(0.5 in)oI the bore surface.

Under some environmental circumstances, steels may be subject to transgranular stress-corrosion cracking. Tendencies vary with different compositions .but additional resistance may be provided by surface treatments that lead to compressive residual stress.

Specifications:

| Specification |

OD |

ID |

Connection |

Body |

| Style |

OD |

Inner and outer thread shoulder

Chamfer mm

|

| mm |

inch |

mm |

inch |

mm |

inch |

Center area mm |

End area mm |

| 6 5/8FH |

168.3 |

6 5/8 |

114.3 |

4 1/2 |

6 5/8FH |

209.6 |

8 1/4 |

195.70 |

184.2 |

176.21 |

| 1/2FH |

139.7 |

5 1/2 |

92.1 |

3 5/8 |

1/2FH |

177.8 |

7 |

170.7 |

152.4 |

144.5 |

| NC50 |

127.0 |

5 |

76.2 |

3 |

NC50 |

168.3 |

6 5/8 |

154.0 |

139.7 |

130.2 |

| NC46 |

114.3 |

4 1/2 |

71.4 |

2 13/16 |

NC46 |

158.8 |

6 1/4 |

145.3 |

127.0 |

117.5 |

| NC38 |

88.9 |

3 1/2 |

52.39 |

2 1/16 |

NC38 |

120.7 |

4 3/4 |

116.3 |

101.6 |

92.1 |

| NC31 |

73.03 |

2 7/8 |

50.8 |

2 |

NC31 |

104.8 |

4 1/8 |

100.4 |

84.1 |

81.0 |